Leader in Pipeline Inspection Technology

Shenyang Lujie Pipeline Inspection Co., Ltd. has been engaged in the research and pipe inspection technology for more than 20 years. We have promoted the development and application of in-pipe inspection technology in China, and China has become one of the few countries in the world to carry out research, manufacture and service of intelligent in-pipe inspection equipment.

Professional Inspection

We Provide a Wide Range of In-pipe Inspection Services

Our inspection services include cleaning PIG, EGP, MFL,etc. We have advanced equipment and rich experience to provide serve with high quality inspection solutions.

Cleaning PIG Services

We provide cleaning PIG services for oil pipelines and gas pipelines of all sizes, cleaning wax, soft dirt, iron oxide and construction debris from the inner wall of the pipeline to improve the efficiency of pipeline transportation, reduce corrosion and abrasion loss of the inner wall, and extend the service life of the pipeline.

EGP

We use EGP to detect pipe deformation, EGP can detect dents, deformations, ellipticity, minimum inside diameters, and changes in pipe wall thickness, and EGP can record the mileage of characteristics.

MFL

We provide MFL for pipeline corrosion defects detection, through the detection of pipeline internal and external wall corrosion defects, weld defects, construction damages and pipeline characteristic lengths, etc., to reduce the risk of pipeline operation and minimize the occurrence of operational accidents.

IMU

We provide IMU centerline mapping service, which can accurately map out the geographic coordinates of the pipe and can perform pipe bending strain calculations.

Lujie Inspection Services

Introduction of Pipeline Inspection

Pipeline inspection equipment through the pressure difference of the conveying medium running in the pipeline, the use of leakage detection technology, ultrasonic detection technology and other non-destructive testing technology to truly detect and record the corrosion of the internal and external walls of the pipeline (corrosion of the size of the area, the shape of the depth and the occurrence of the site), depression deformation, weld defects, cracks, mechanical damage, pipe characteristics, pipe length and other conditions.

- Basic process of inspection;

- Technical principles of inspection;

- Why choose us?

Specialized pipeline Inspection

Find Out Our Equipment

We offer a wide range of equipment, including cleaning PIG (complete), EGP, MFL, and ECT. These are used in a wide range of inspection services to provide high-quality inspection results.

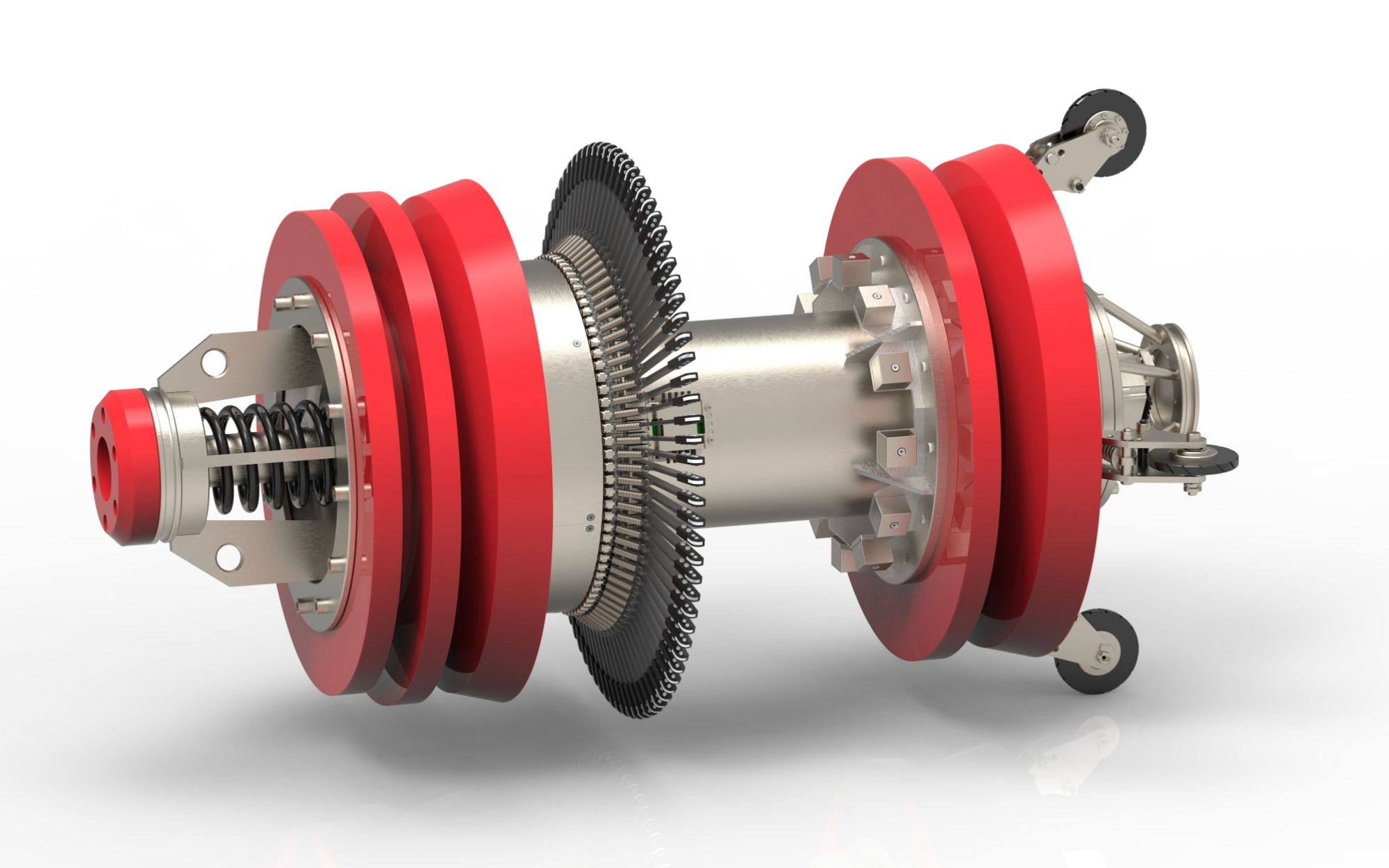

Cleaning Pig(Complete Sets)

We provide efficient and reliable cleaning PIG to ensure an unobstructed flow inside the pipes.

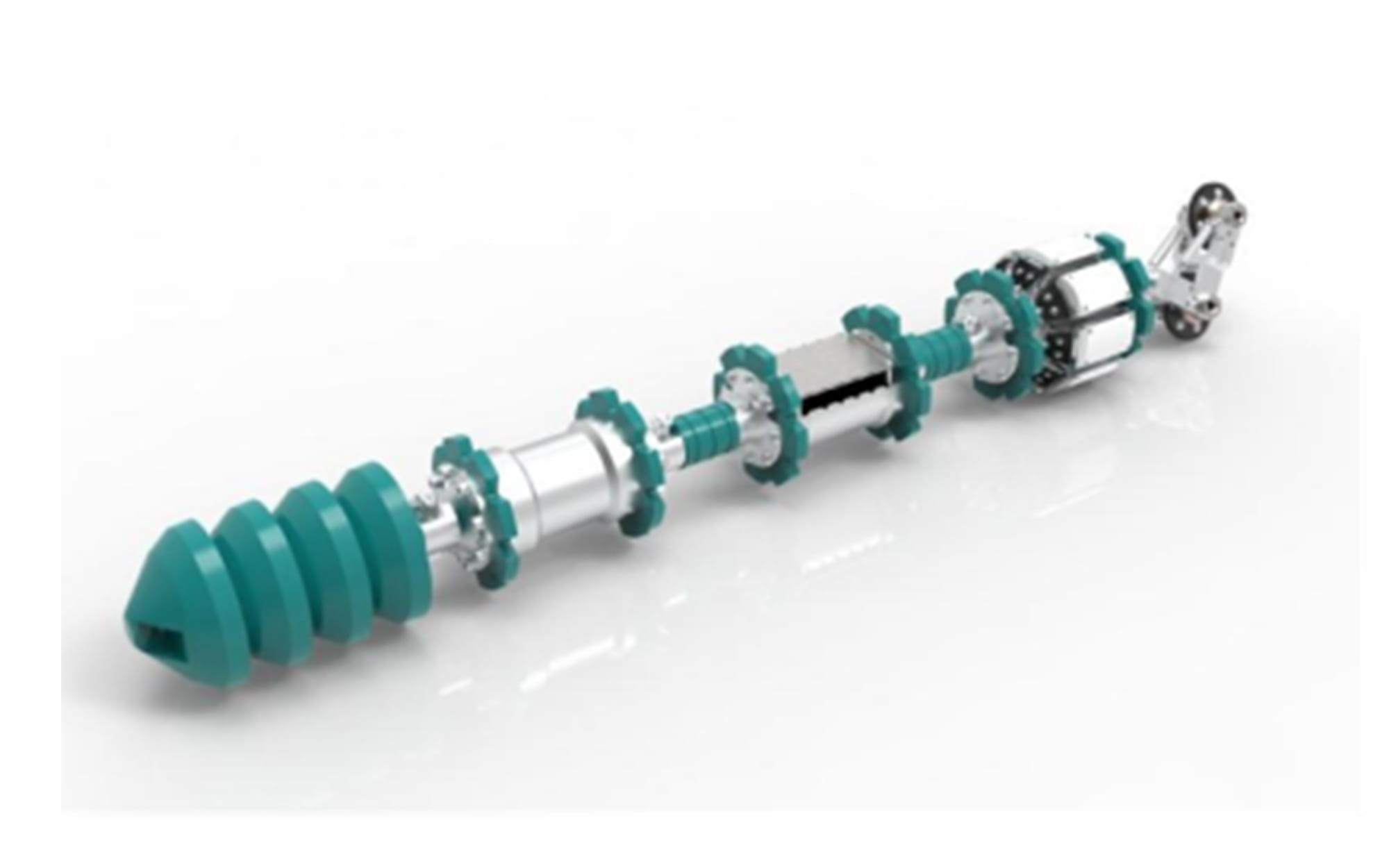

EGP

Our EGP accurately measure the shape and deformation of pipes.

MFL

Our MFL detectors are able to quickly and accurately detect defects and damage in pipelines.

ECT

Our ECT are capable of comprehensively detecting conditions and problems within pipelines.

Professional Pipeline Inspection Services

Using state-of-the-art techniques and equipment, our team of professionals provides you with a comprehensive in-pipe inspection and assessment report so that you can identify and resolve potential problems in a timely manner, thereby reducing maintenance costs and extending the life of your pipes.

Lujie Inspection Services

Contact us

Welcome to contact us by phone, email or online form and we will be happy to assist you. |