Lujie In-pipe Inspection Services

Shenyang Lujie Pipeline Inspection Co., Ltd. is a leader in the pipeline inspection industry and is committed to providing you with professional pipeline inspection solutions.

IN-LINE INSPECTION PROCESS

Introduction of pipeline inspection

Pipeline inspection equipment through different the transmission medium pressure in the pipeline operation, the use of MFL, UT and other non-loss detection technology to detect and record the corrosion of the pipeline internal and external walls (corrosion of the size of the area, shape, depth and occurrence of the site, depression and deformation, weld defects, cracks, mechanical damage, pipeline characteristics, pipeline length, etc.).

01

02

Preparation of Construction Program Process

03

Cleaning PIG

3.1

Pipe cleaning operation stopping criteria for the total weight of clear impurities ≤ 5kg

04

EGP

4.1

Pipeline modification

05

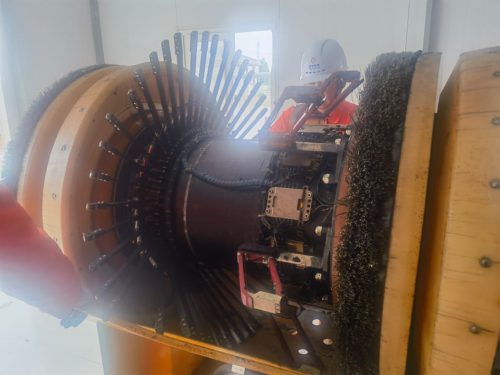

MFL

5.1

MFL tracker

06

Preliminary Report

07

Excavation Verification

08

Pipeline Integrity and Risk Assessment

09

Integrity Inspection Report

PIPELINE CLEANING SERVICE

Purpose of PIG Cleaning: To clean the wax, soft dirt, iron oxide and construction residues on the inner wall of the pipeline, to improve the pipeline conveying efficiency, to reduce the corrosion of the inner wall and the loss of abrasion and sunshine, and to prolong the service life of the pipeline.

Pipe cleaning service stopping standard: The stopping standard of pipe cleaning operation is that the total weight of impurities in the pipe ≤ 5 liters.

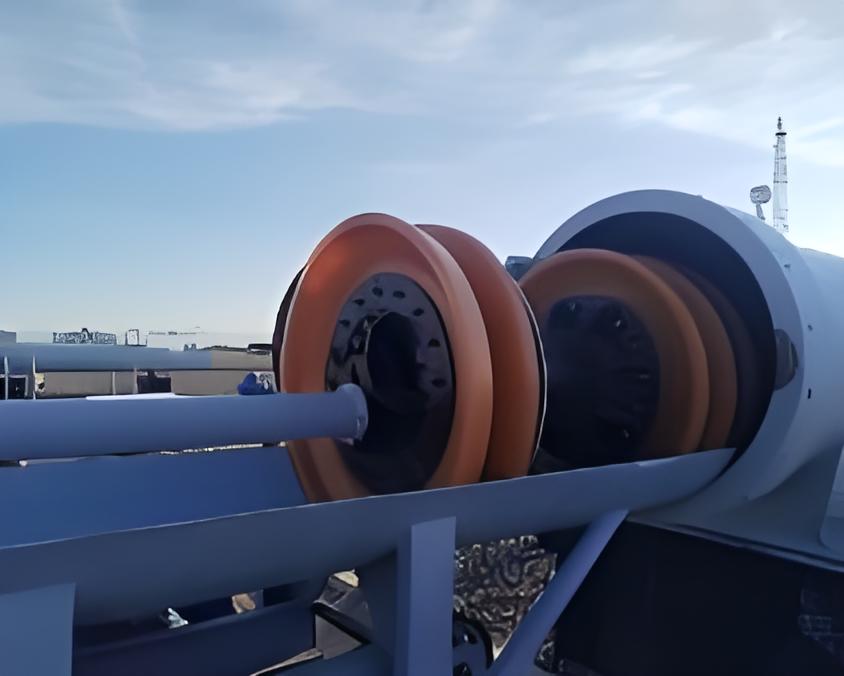

EGP

The EGP can detect the depression, ovality deformation, wall thickness change of the pipeline, and various pipeline accessories that cause the inner diameter of the pipeline to change

MFL

MFL can complete the detection of pipe defects, metal loss, pipe material changes, internal and external defect discrimination and pipe characteristics (pipe hoop, repair scars, bend, weld tee, etc.), and provide comprehensive information of defect area, depth, orientation, location and so on.

Our company produces and sells 6”-56” three-axis ultra-high-definition axial excitation magnetic flux leakage internal detector, above 28’’ series magnetic flux leakage internal detector with self-balancing speed control valve.

IMU

The inertial navigation system is mounted in the in-pipe detector (pipe cleaner), and the inertial navigation system is clocked with the pipe inspection tool through the synchronization method, and the whole system is pushed forward by the medium in the pipe. The core components of the system are three-axis orthogonal fiber optic gyro and three-axis orthogonal accelerometer, and the auxiliary signals are odometer information and magnetic marker information, which can calculate the position and attitude information of any point of the detector when it is running inside the pipeline, so as to accurately depict the pipeline centerline trajectory.

IN-LINE INSPECTION PROCESS

Other Detections

Professional Pipeline Inspection Services

Using state-of-the-art techniques and equipment, our team of professionals provides you with a comprehensive in-pipe inspection and assessment report so that you can identify and resolve potential problems in a timely manner, thereby reducing maintenance costs and extending the life of your pipes.