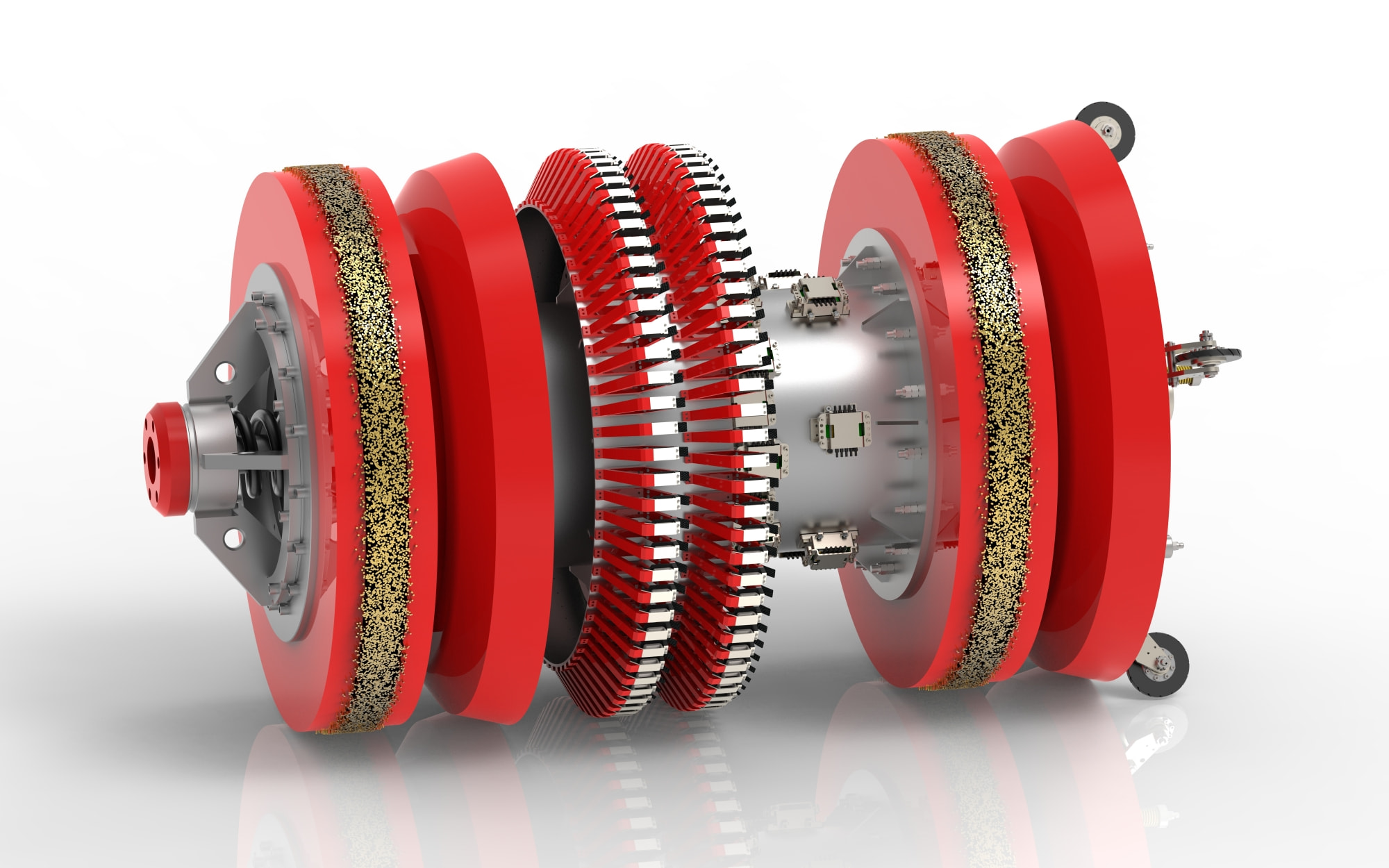

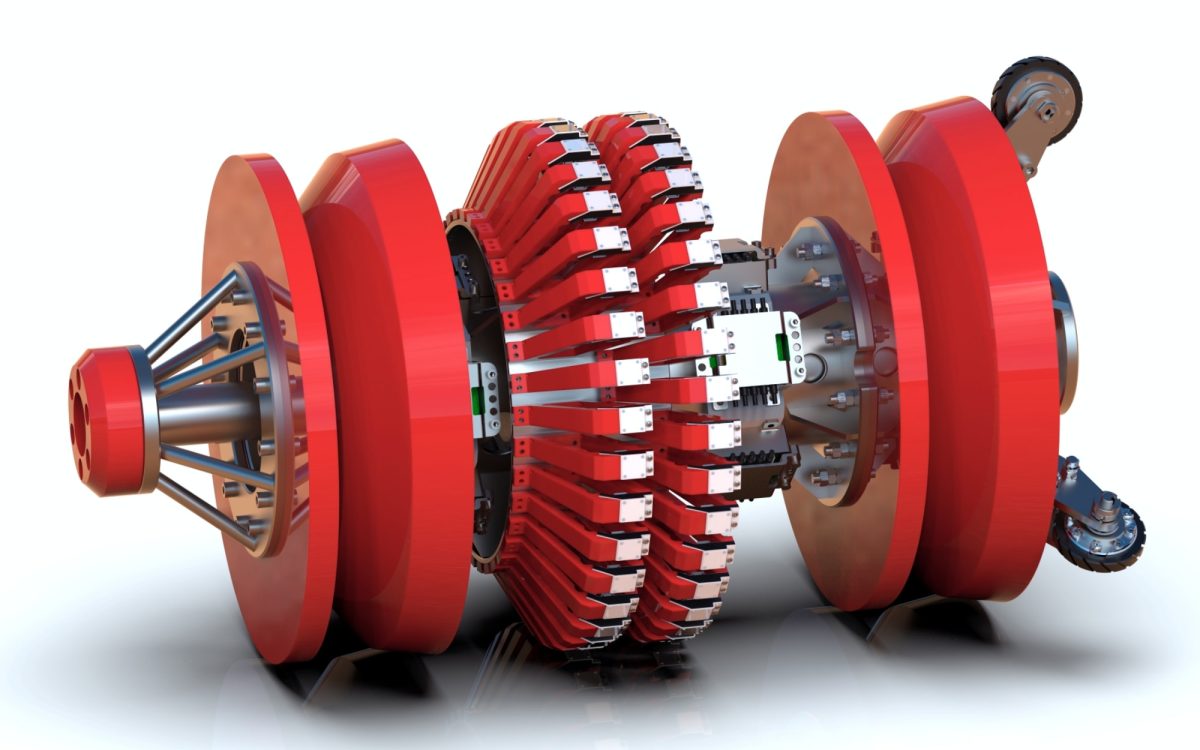

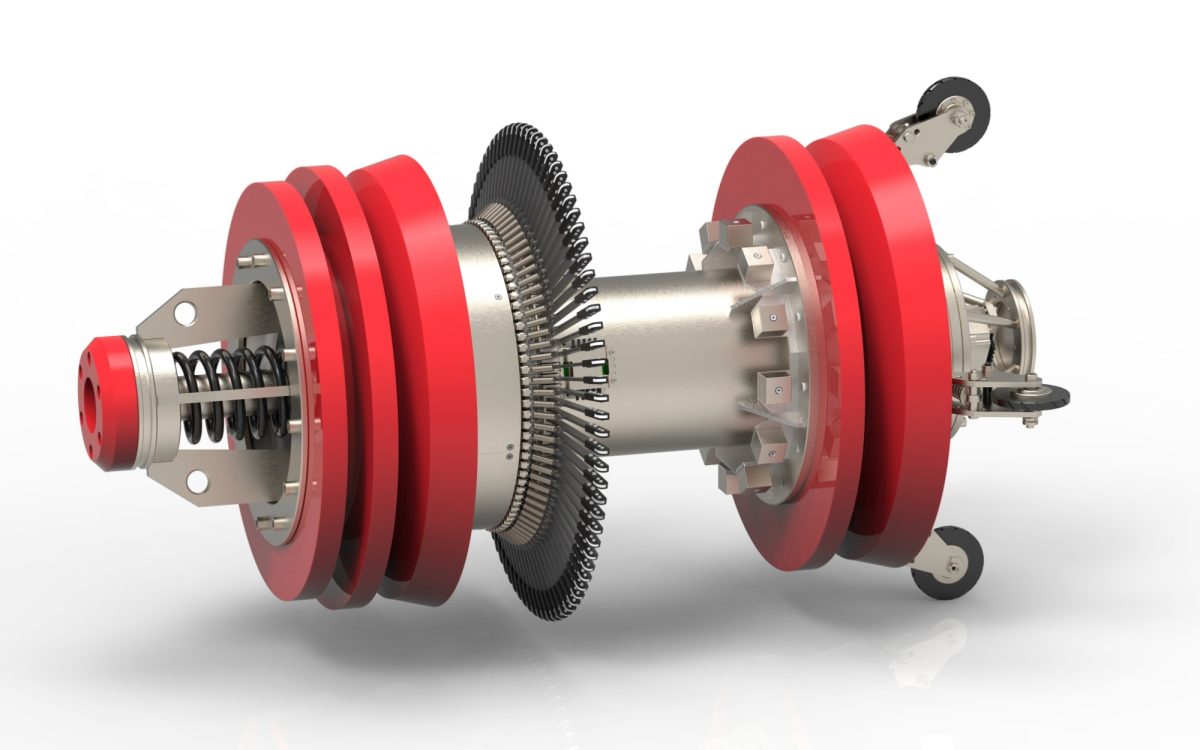

CRACK DETECTOR

Cracks are one of the most dangerous defects in long-distance pipelines, and they are also the main cause of pipeline failure. The occurrence and expansion of cracks will cause stress concentration in the pipeline, which is prone to failures such as brittle fracture, fatigue damage and corrosion damage. Detection can improve the performance and reliability of the pipeline. The pipeline crack detector is based on the balanced field electromagnetic method, which can effectively detect cracks in any direction of inner wall pipeline within 10mm, the internal cracks of the pipe wall, the internal cracks in circumferential welds and the internal cracks in straight welds.

Introduction

Cracks are one of the most dangerous defects in long-distance pipelines, and they are also the main cause of pipeline failure. The occurrence and expansion of cracks will cause stress concentration in the pipeline, which is prone to failures such as brittle fracture, fatigue damage and corrosion damage. Detection can improve the performance and reliability of the pipeline. The pipeline crack detector is based on the balanced field electromagnetic method, which can effectively detect cracks in any direction of inner wall pipeline within 10mm, the internal cracks of the pipe wall, the internal cracks in circumferential welds and the internal cracks in straight welds.

Technology

All-round crack detection:

The balanced field crack detection method is not restricted by direction, and can detect axial cracks, circumferential cracks and various oblique cracks, realizing all-around crack detection.

The pipeline crack detector is based on the balanced field electromagnetic method, which can effectively

detect the intemal and extermal cracks of the pipe wall, the cracks at the circumferential welds and the cracks at the

straight welds.

It can detect cracks on the weld:

The cracks in the weld can be distinguished by the characteristics of the defect signal and the degree of amplitude change.

Service Advantage

Specs.

Detection range

For cracks within 10mm from the inner surface, with the opening width more than 0.1mm, the height (depth)more than 10%WT and the length more than 25mm, the detection and the recognition rate of cracks is 90%.

Detection accuracy

Certainty accuracy = 90%.

Measurement accuracy of crack depth of inner

surface opening: ±2mm.

Measurement accuracy of self-height of buried crack: ± 3mm.

Length measurement accuracy: ± 10mm.

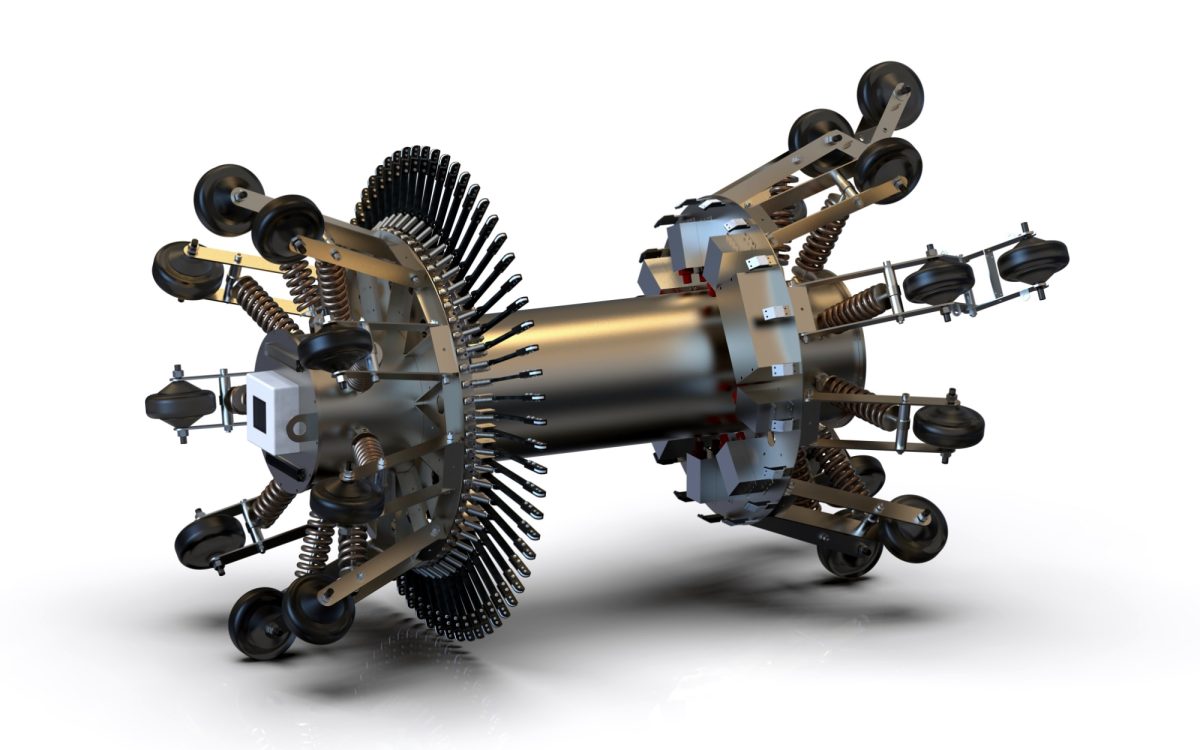

Gallery

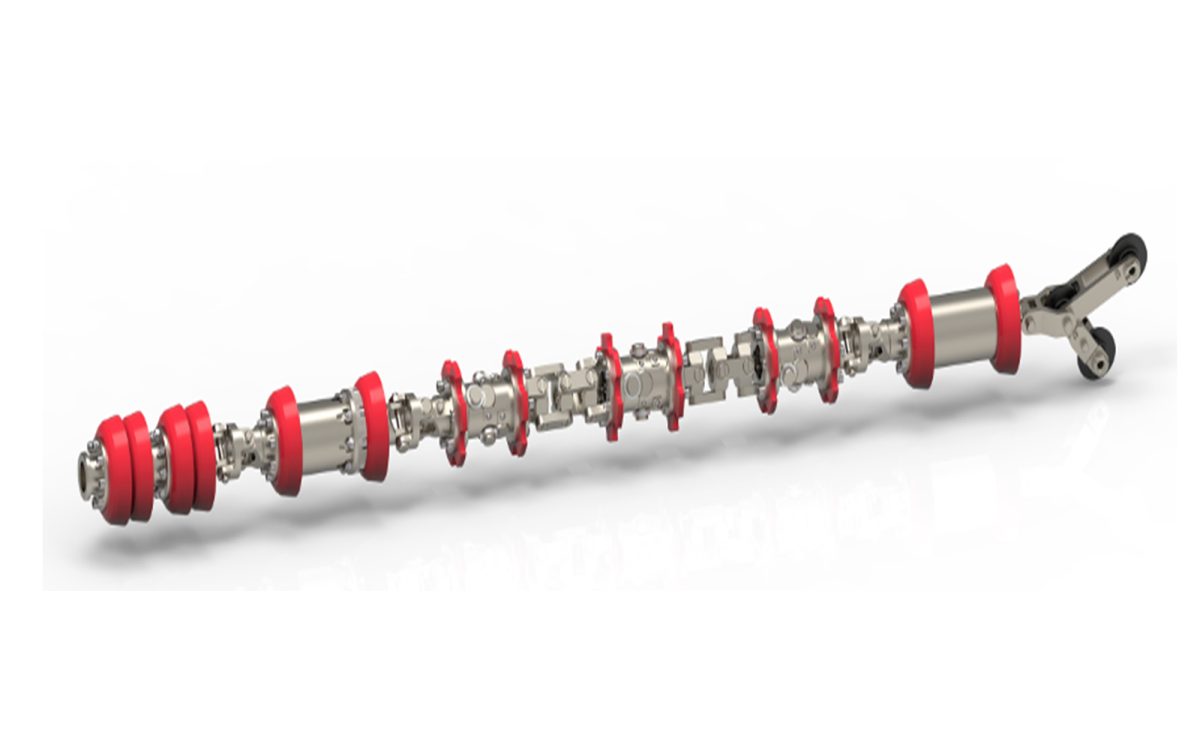

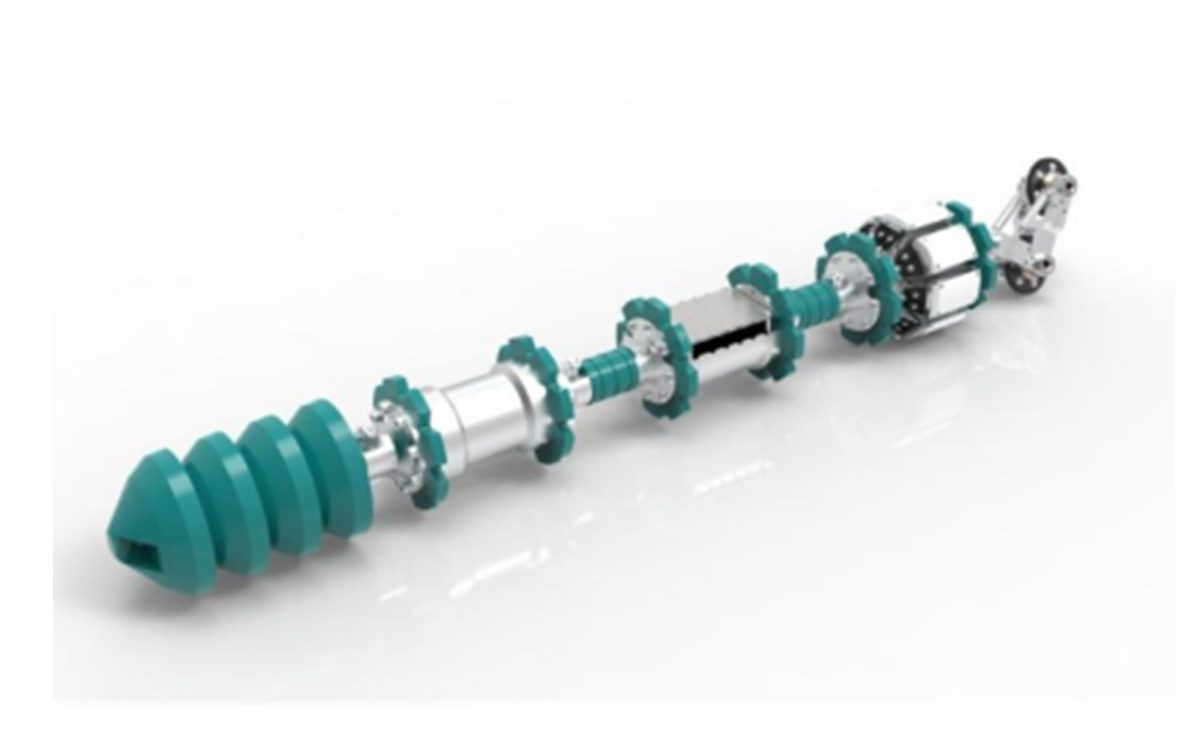

Introduction of Pipeline Inspection

Our professional internal inspection services are available for a wide range of oil and gas pipelines with different pipe diameters, and can address both macro-defects and micro-stresses.