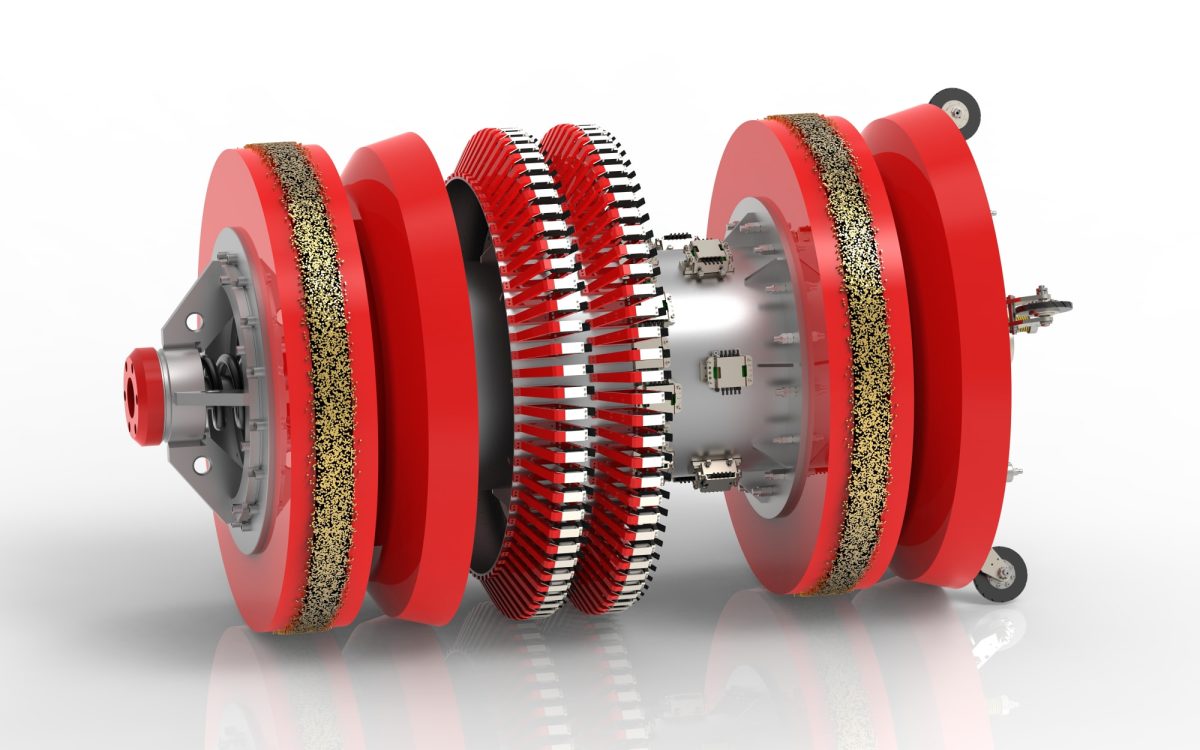

BENDING STRAIN DETECTOR

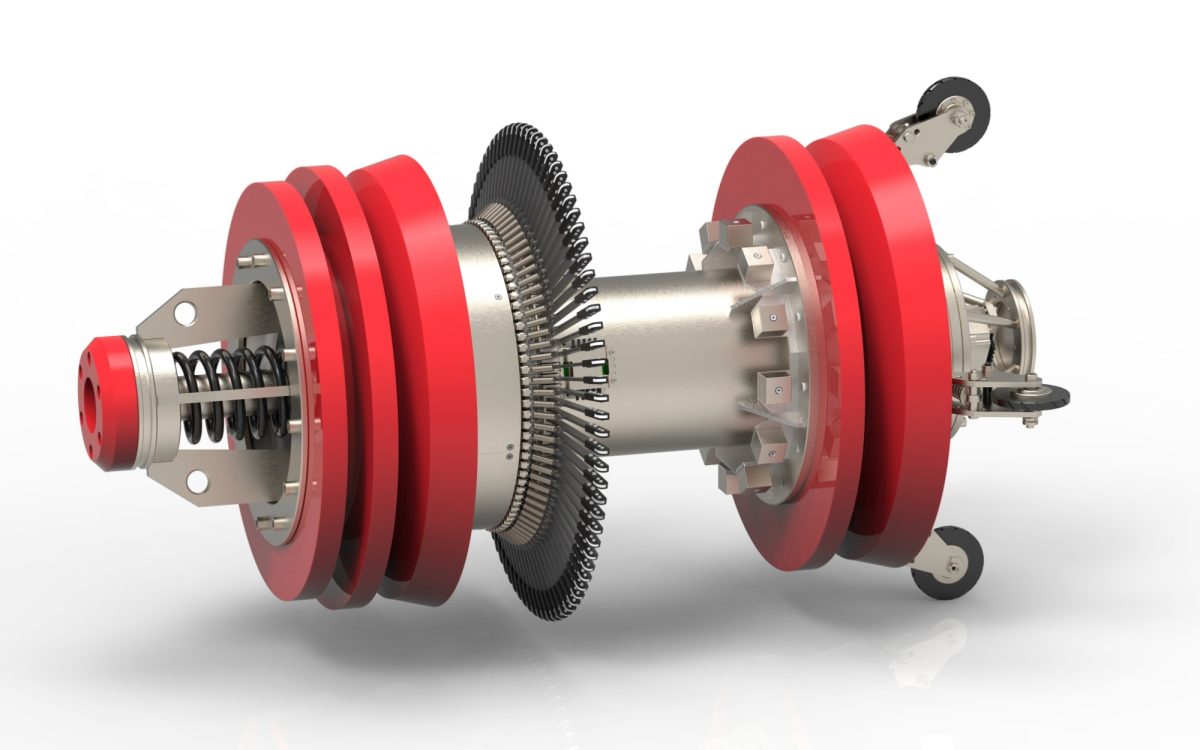

The bending strain detector uses the principle of inverse magnetostriction, that is, the force-magnetic coupling relationship between the pipe strain and the surface magnetic field under an external magnetic field to realize the detection and quantitative analysis of the pipe bending strain.

The bending strain detector can carry out the continuous bending stress of the pipeline, accurately identify the stress and strain area, and carry out effective evaluation.

Introduction

The bending strain detector uses the principle of inverse magnetostriction, that is, the force-magnetic coupling relationship between the pipe strain and the surface magnetic field under an external magnetic field to realize the detection and quantitative analysis of the pipe bending strain.

The bending strain detector can carry out the continuous bending stress of the pipeline, accurately identify the stress and strain area, and carry out effective evaluation.

Technology

High efficiency:

The stress-strain probe is installed on Caliper or MFL, and the detection is completed at one time.

Low detection cost:

The probe can be reused many times.

No coupling agent required:

It is suitable for various product pipeline.

The results can be quantified:

It can realize quantitative analysis of the test results and effectively evaluate the stress and strain of the pipeline.

Service Advantage

Specs.

Technical Parameter

| Axial stress | Percent | |

| Detection threshold at POD= 90% | ±200με | ±0.02% |

| Detection accuracy at 80% certainty | ±100με | ±0.01% |

- Working pressure: 1-12MPa.

- Running speed: 0.5-6m/s.

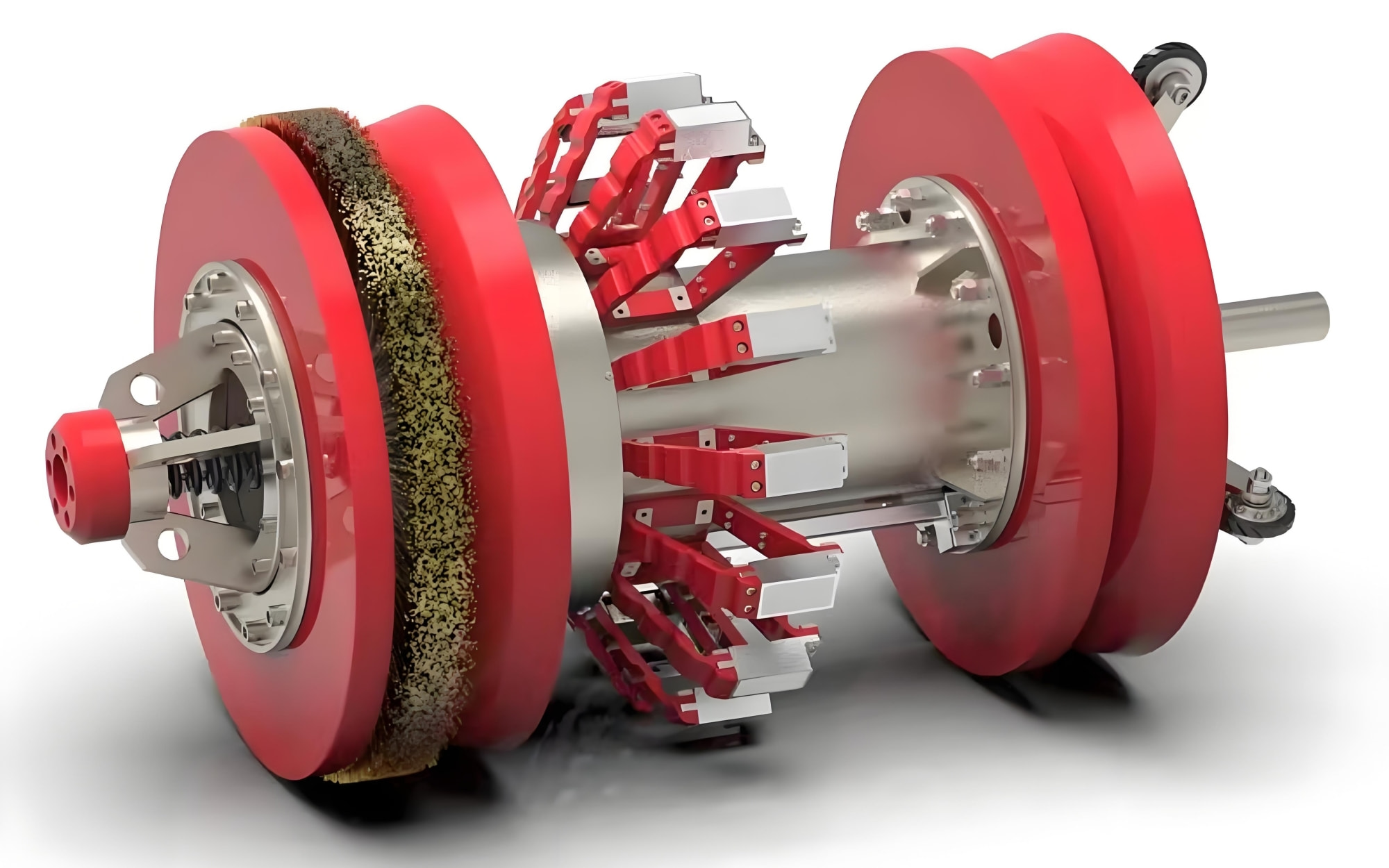

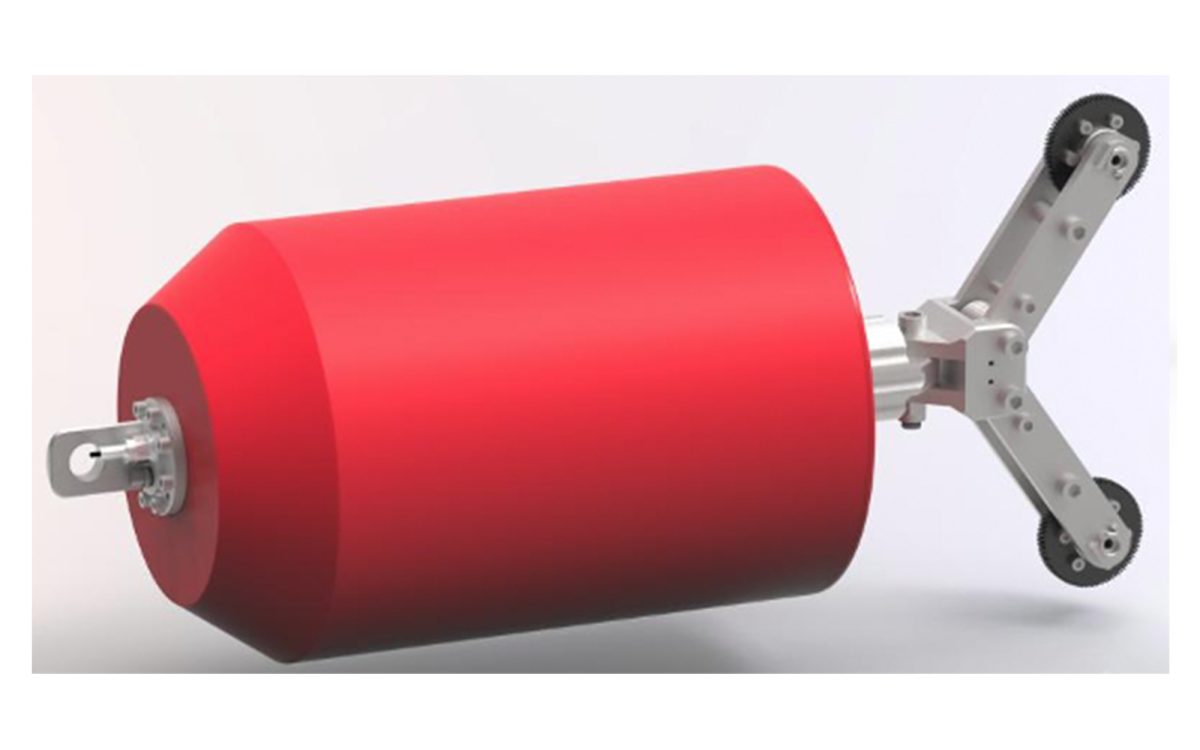

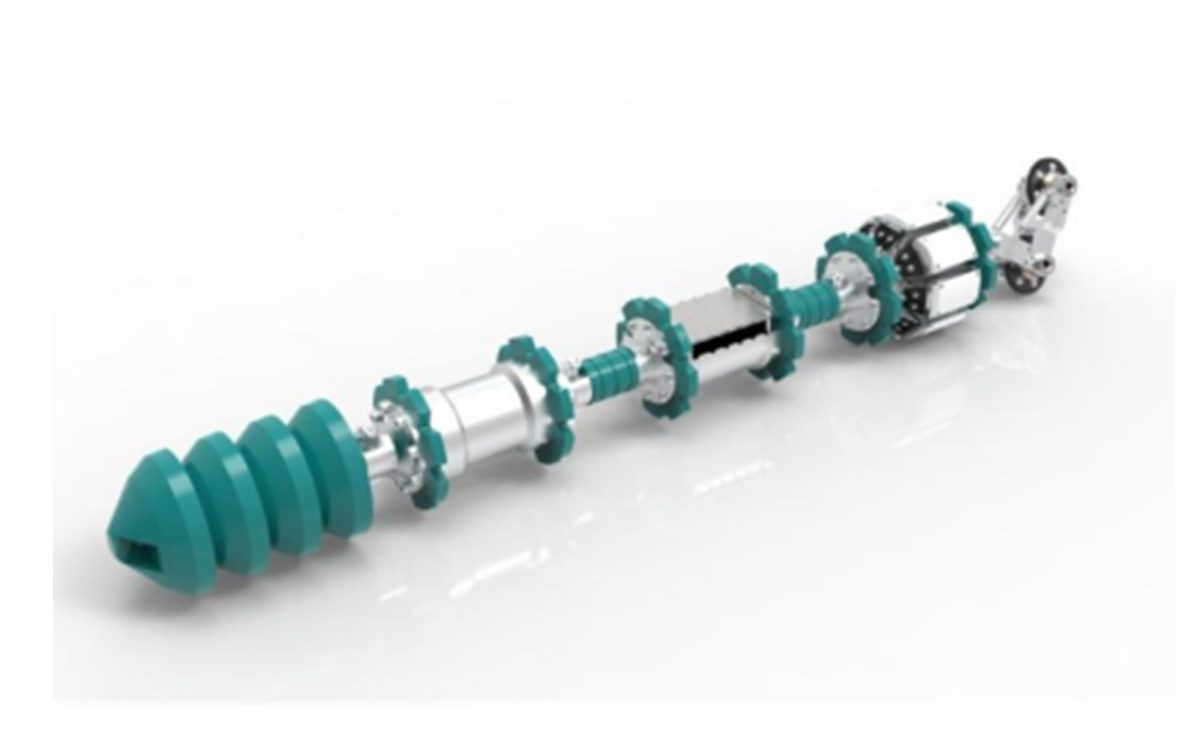

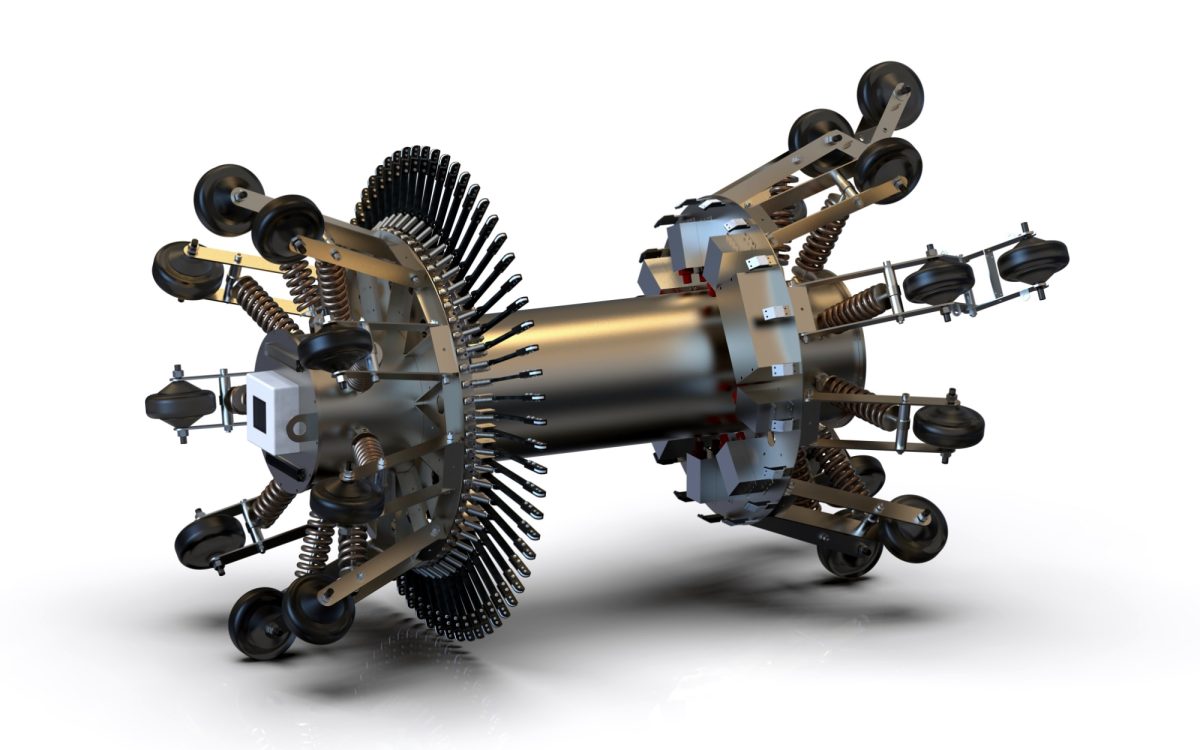

Gallery

Introduction of Pipeline Inspection

Our professional internal inspection services are available for a wide range of oil and gas pipelines with different pipe diameters, and can address both macro-defects and micro-stresses.