MICRO PIPELINE CORROSION EDDY CURRENT DETECTION EQUIPMENT

The micro pipeline corrosion eddy current detector realizes the full coverage of the size, position and distribution of micro pipeline corrosion and high-precision intelligent detection by walking in the pipeline, which solves the technical problem that the corrosion of micro pipeline cannot be comprehensively detected. This system is especially suitable for corrosion detection of special pipelines such as small caliber, complex external space, and inability to carry out external inspection, and has a very wide application prospect in the corrosion detection of pipelines such as special ships, aircraft, and ships.

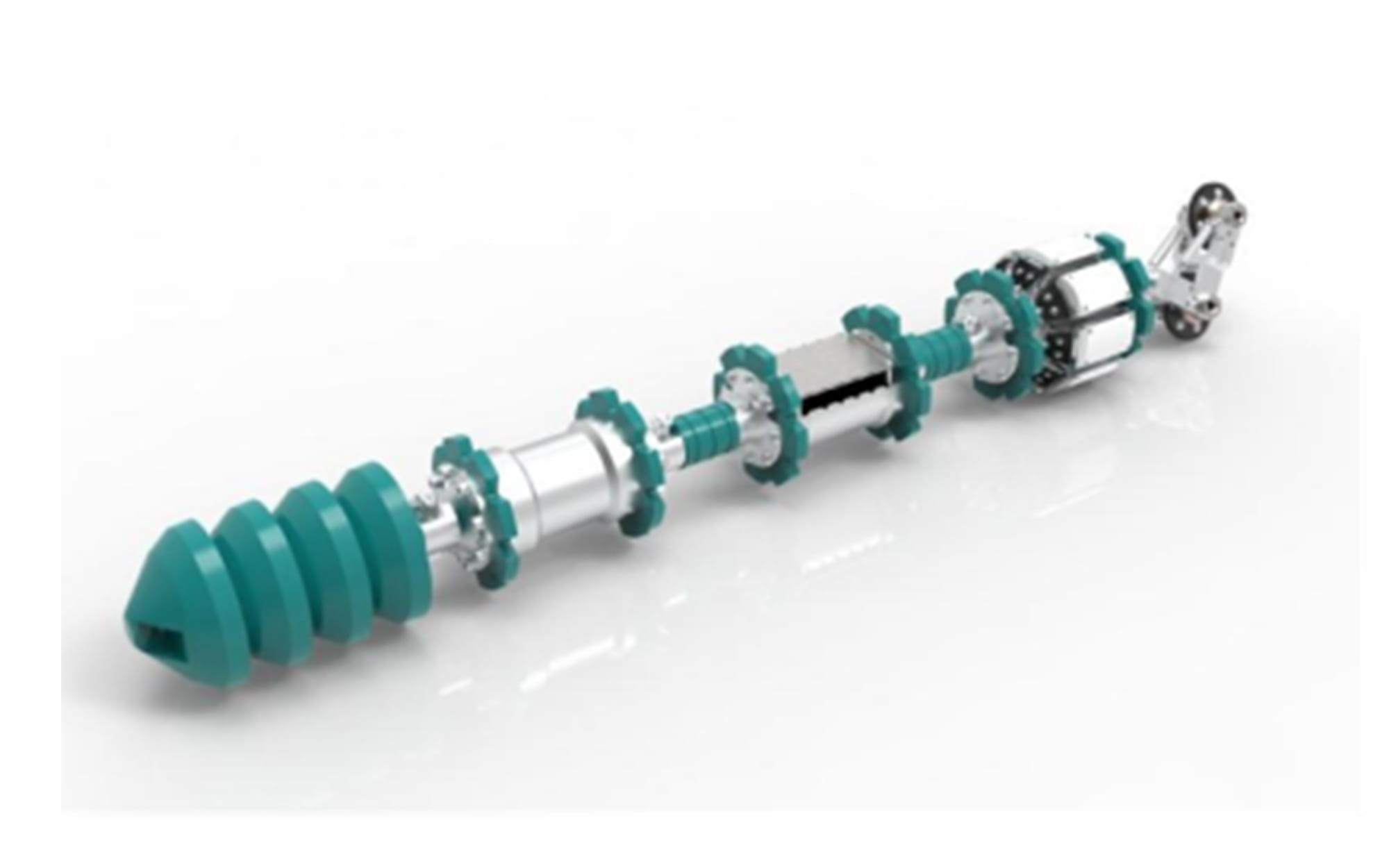

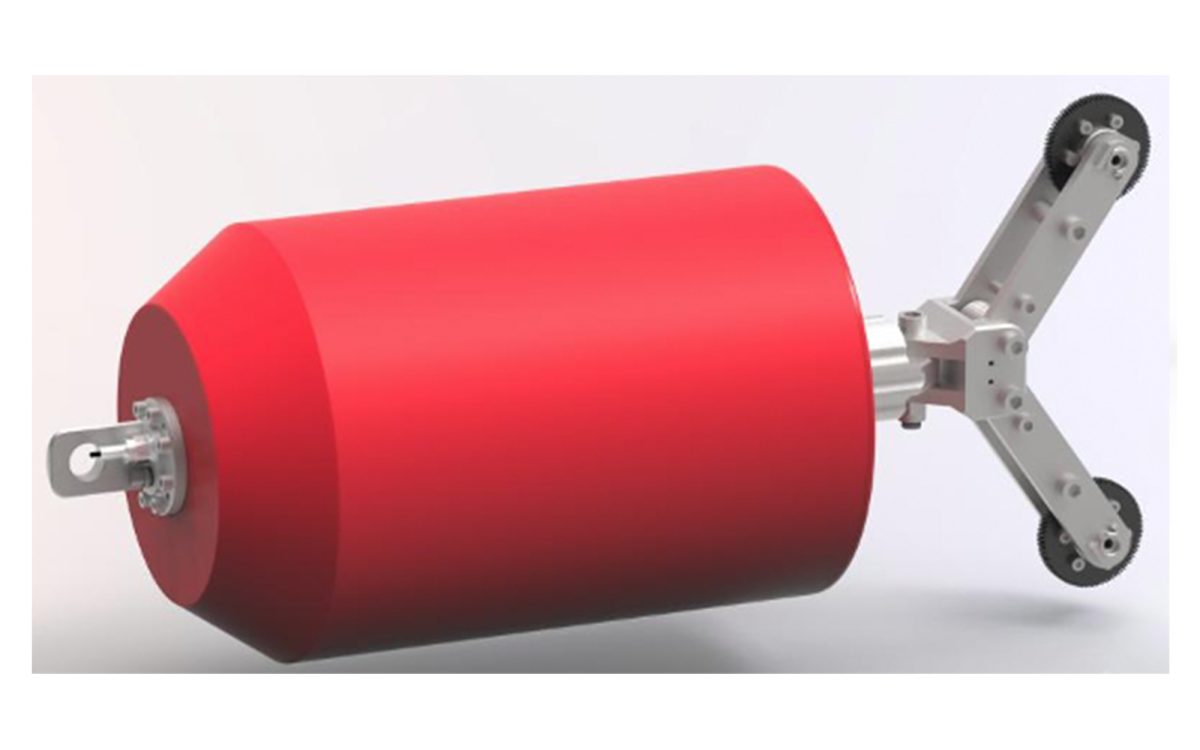

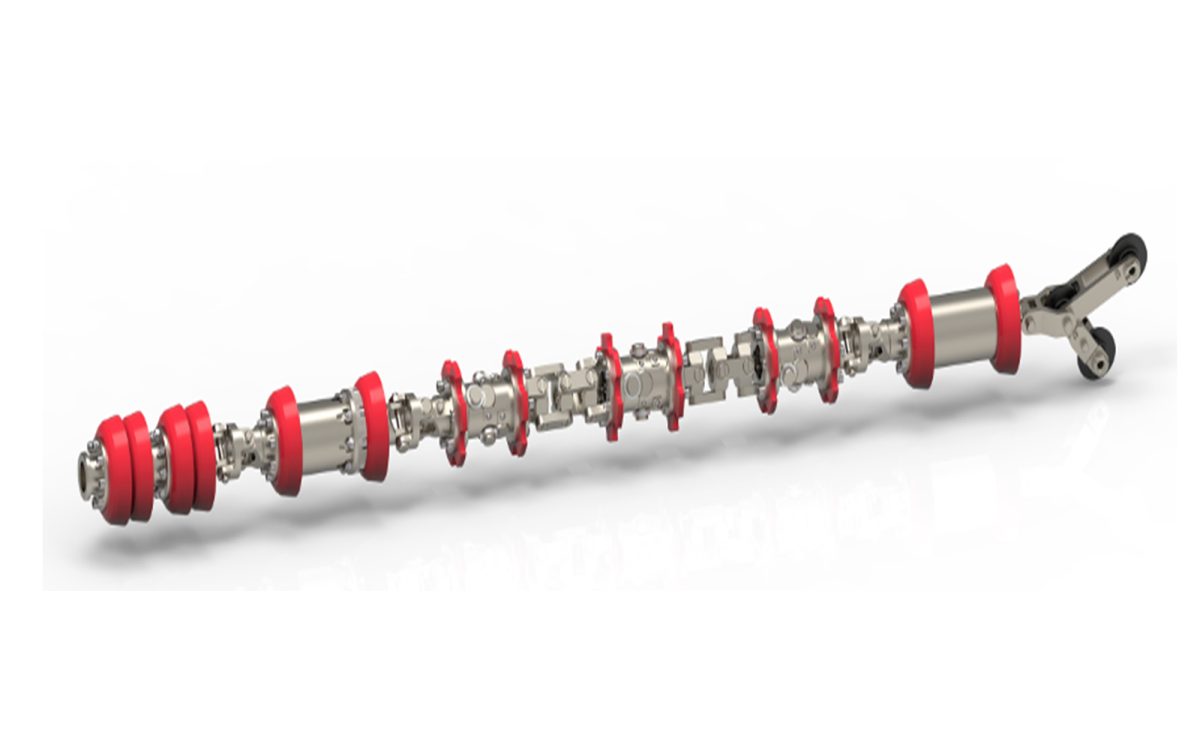

At present, it has four kinds of small-diameter pipeline corrosion eddy current detection equipment of 3.5’’, 4.2’’, 6.6’’ and 8.7’’, which has been successfully applied to the corrosion detection of various types of ship pipelines, making a comprehensive and accurate evaluation of the safety status of pipelines, and providing an important scientific basis for the safety and maintenance decisions of major equipment.

Introduction

The micro pipeline corrosion eddy current detector realizes the full coverage of the size, position and distribution of micro pipeline corrosion and high-precision intelligent detection by walking in the pipeline, which solves the technical problem that the corrosion of micro pipeline cannot be comprehensively detected. This system is especially suitable for corrosion detection of special pipelines such as small caliber, complex external space, and inability to carry out external inspection, and has a very wide application prospect in the corrosion detection of pipelines such as special ships, aircraft, and ships.

At present, it has four kinds of small-diameter pipeline corrosion eddy current detection equipment of 3.5’’, 4.2’’, 6.6’’ and 8.7’’, which has been successfully applied to the corrosion detection of various types of ship pipelines, making a comprehensive and accurate evaluation of the safety status of pipelines, and providing an important scientific basis for the safety and maintenance decisions of major equipment.

Technology

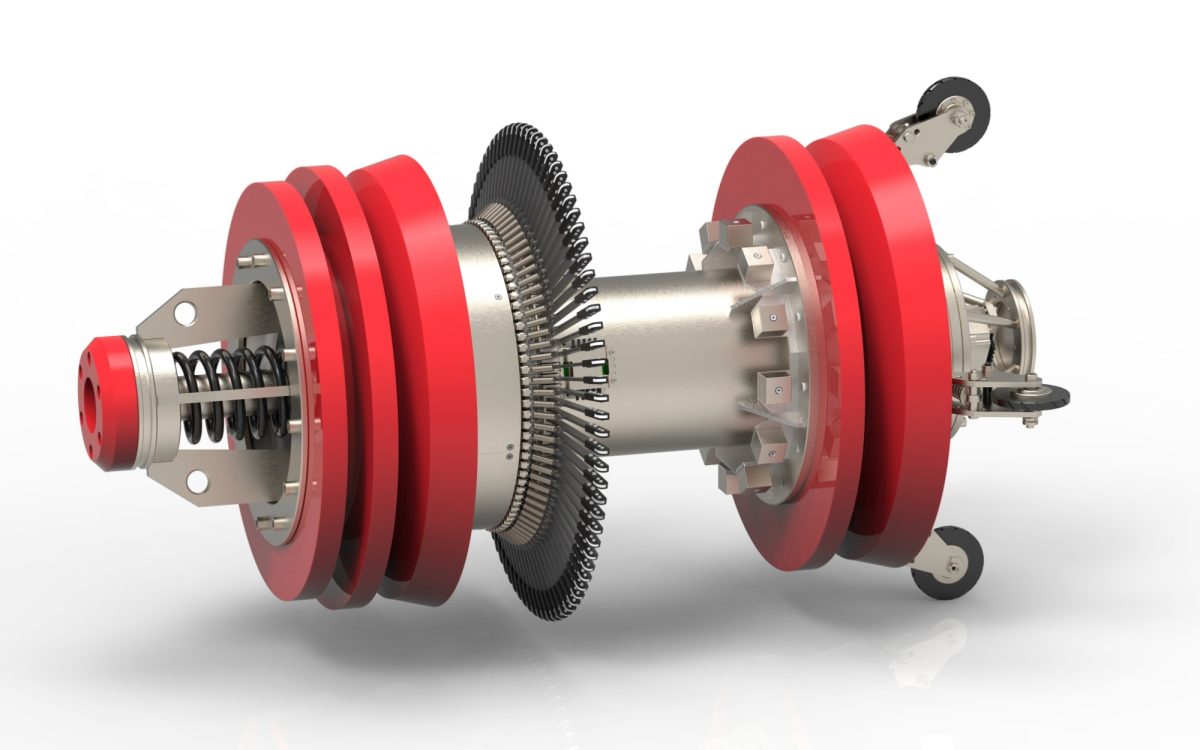

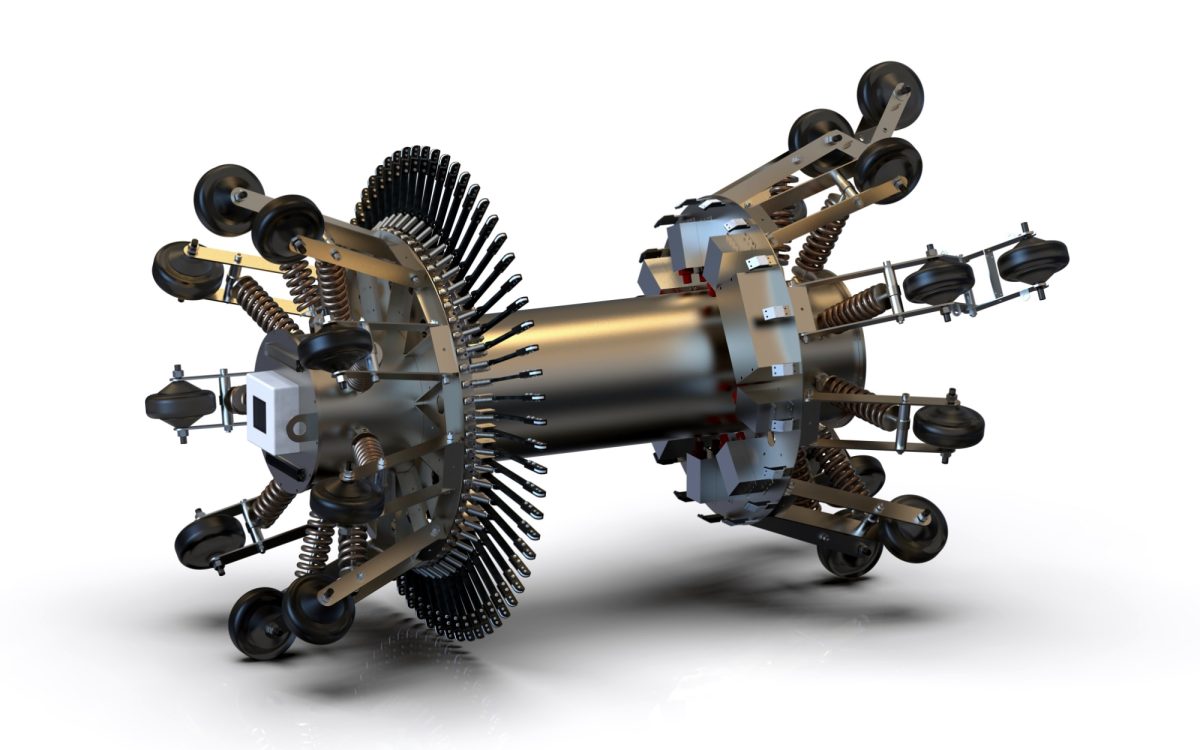

Array scanning technology: 360° full coverage detection is achieved through eddy current probe array, and the detection accuracy is high.

3D C-scan imaging technology: realizes real-time C-scan display of inspection data, which can visually display the position and scope of defects on the pipeline.

Service Advantage

Integrity data management: Provide the original test data and all the test data to achieve lifelong integrity data management.

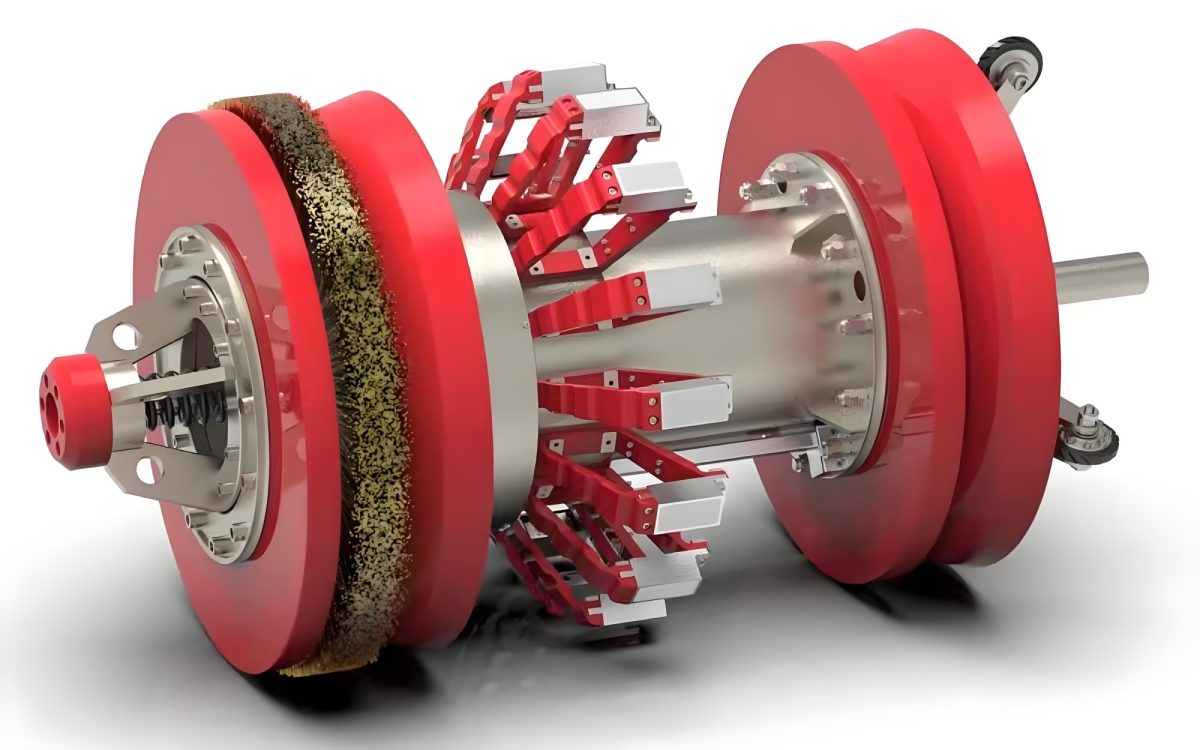

Exclusive customized detector: Customized detector according to the actual working conditions of the pipeline, which can realize the detection in the pipeline under special working conditions such as large deformation and variable diameter.

Analysis software lifetime upgrade and maintenance: free upgrade and maintenance of customer software, free software consultation.

Exclusive service engineer: professional answer to engineering problems on site, and can assist customers to solve engineering problems at any time.

Specs.

Technical Parameter

| Tool sizes available | 3.5’’-56’’ |

| Pipeline product | Crude oil, refined oil, natural gas, sea water, air, etc. |

| Product temperature range | 0 ℃-75 ℃ |

| Maximum operating pressure | ≤12MPa |

| Operating speed range | ≤4m/s |

| Minimum pipeline bend radius | 1.5D |

| Maximum operating time | 50h |

| Maximum inspection length | ≥350km |

Detection Accuracy

| Depth at POD=90% | 1.5mm |

| Depth maximum | 10mm |

| Depth sizing accuracy at 80 % certainty | ±1.3mm |

| Length sizing accuracy at 80 % certainty | ±6mm |

| Width sizing accuracy at 80 % certainty | ±5mm |

Positioning accuracy

| Axial positioning accuracy at Certainty = 90%. | The distance error between the feature and the reference girth weld is less than 0.1m, and the distance is the nearest reference point ±l*1‰ |

| Circumferential

positioning Accuracy at Certainty = 90% |

±5° |

| P.S:l—Calibration distance | |

Gallery

Introduction of Pipeline Inspection

Our professional internal inspection services are available for a wide range of oil and gas pipelines with different pipe diameters, and can address both macro-defects and micro-stresses.