SELF-PROPELLED ROBOT

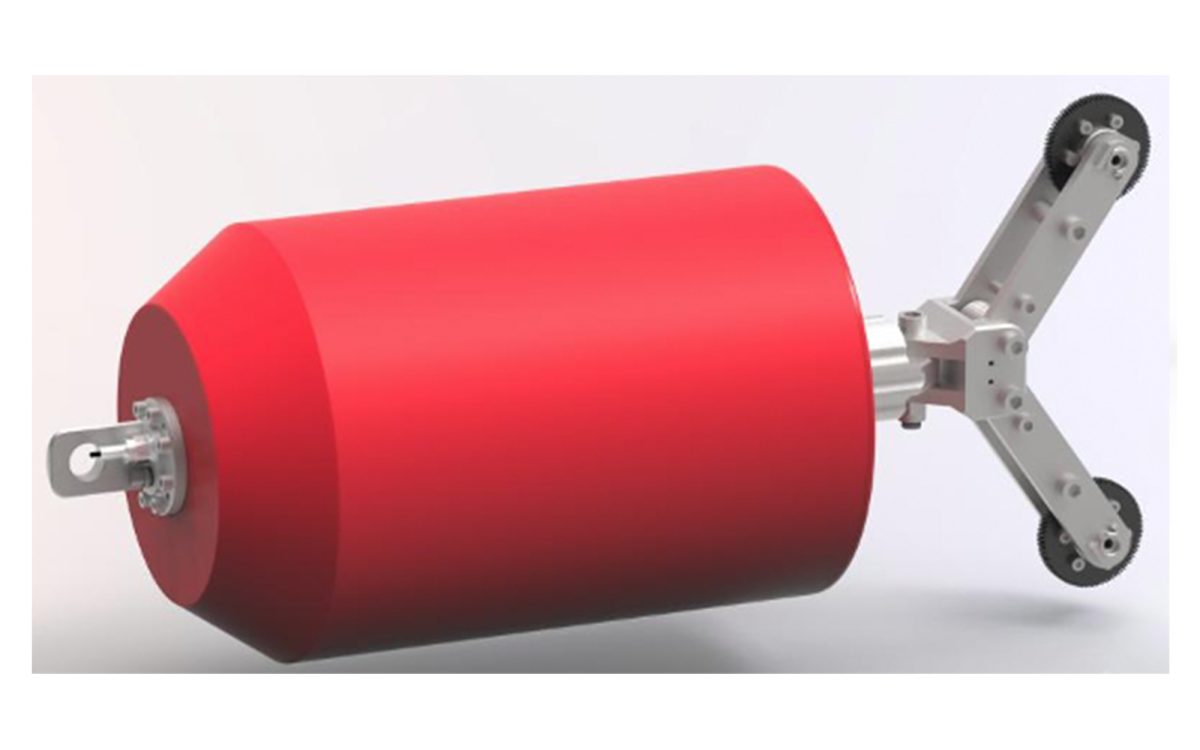

The self-propelled robot can complete the detection work through autonomous crawling, which can implement the geometric deformation detection and centerline mapping before the new pipeline is put into production, providing basic data for the new pipeline.

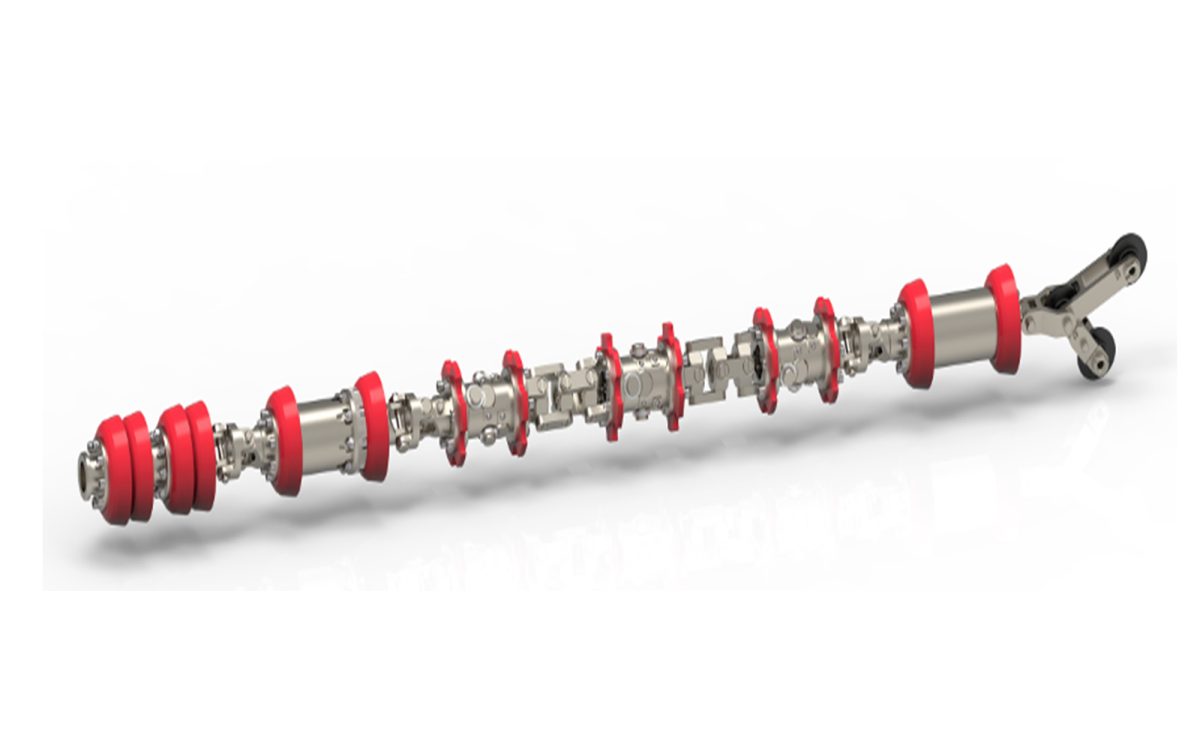

Our company has a full range of 8’’-56’’ SELF-PROPELLED ROBOT, and has completed a number of new pipeline inspections, with a cumulative detection mileage of nearly 5,000 kilometers and a single longest detection distance of 189km.

Introduction

The self-propelled robot can complete the detection work through autonomous crawling, which can implement the geometric deformation detection and centerline mapping before the new pipeline is put into production, providing basic data for the new pipeline.

Our company has a full range of 8’’-56’’ SELF-PROPELLED ROBOT, and has completed a number of new pipeline inspections, with a cumulative detection mileage of nearly 5,000 kilometers and a single longest detection distance of 189km.

Technology

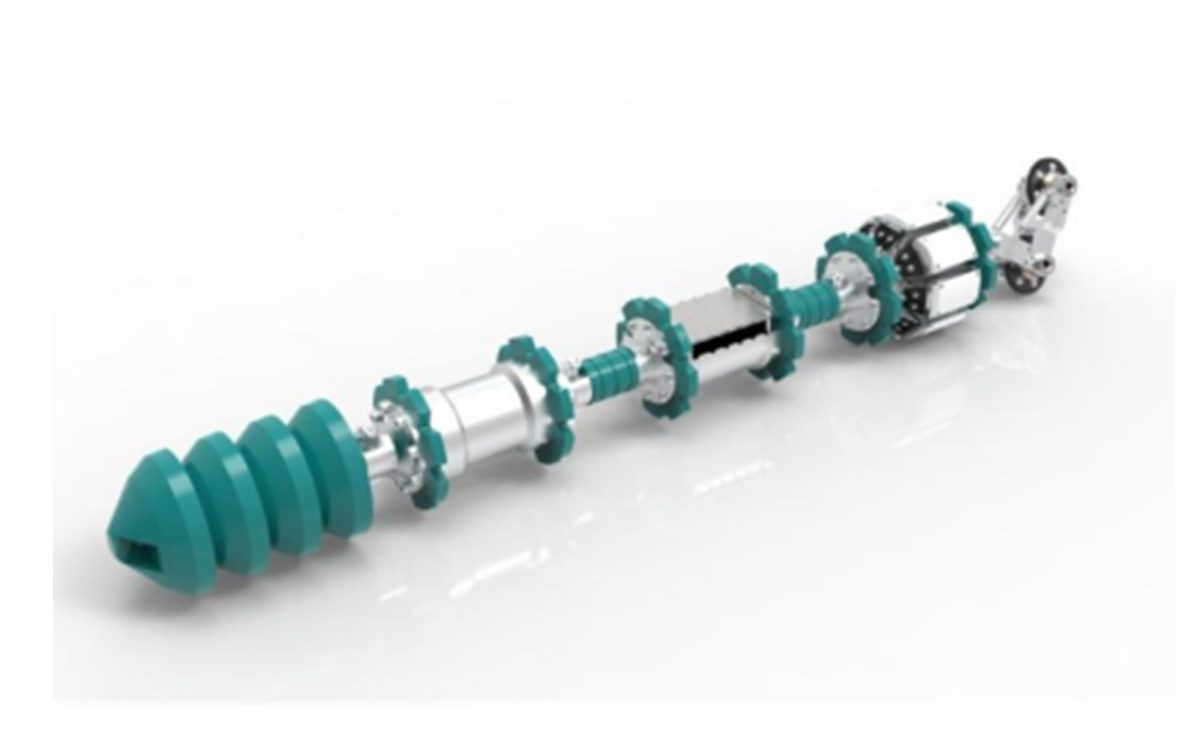

Intelligent control and self-driving system:

The high-performance drive control system autonomously completes the climbing and downhill control to ensure that the detector travels at a constant speed.

Ultra HD video system:

The front end of the crawling detector carries an ultra-high-definition imaging system, which stores images and synchronously collects geometric detection data, and assists in the analysis of foreign objects and deformations in the pipeline.

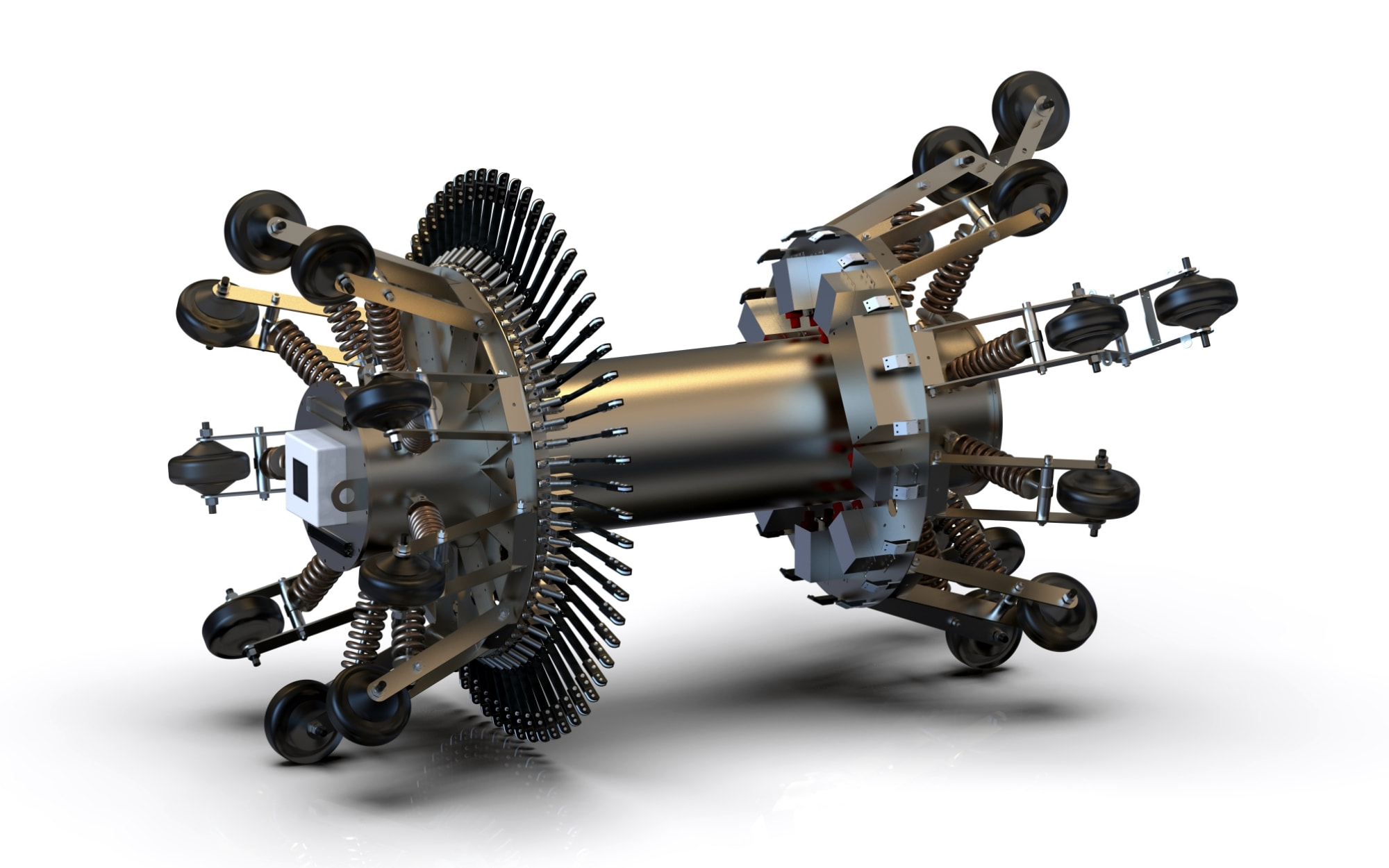

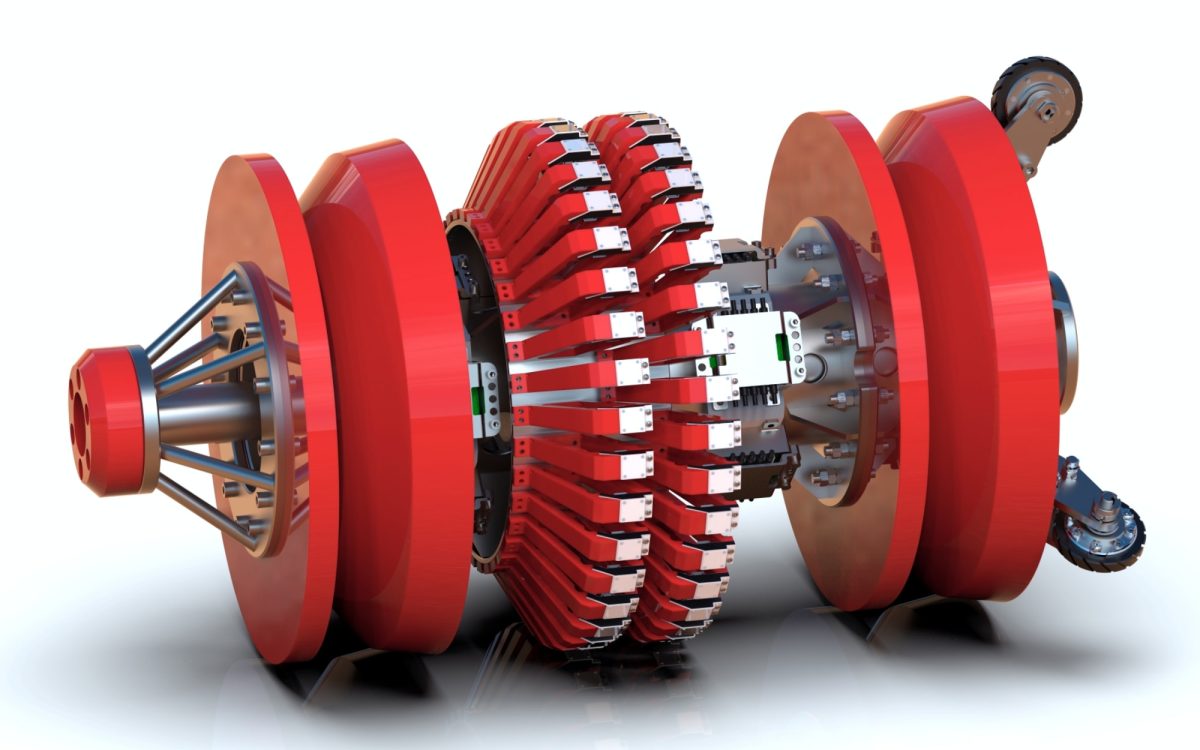

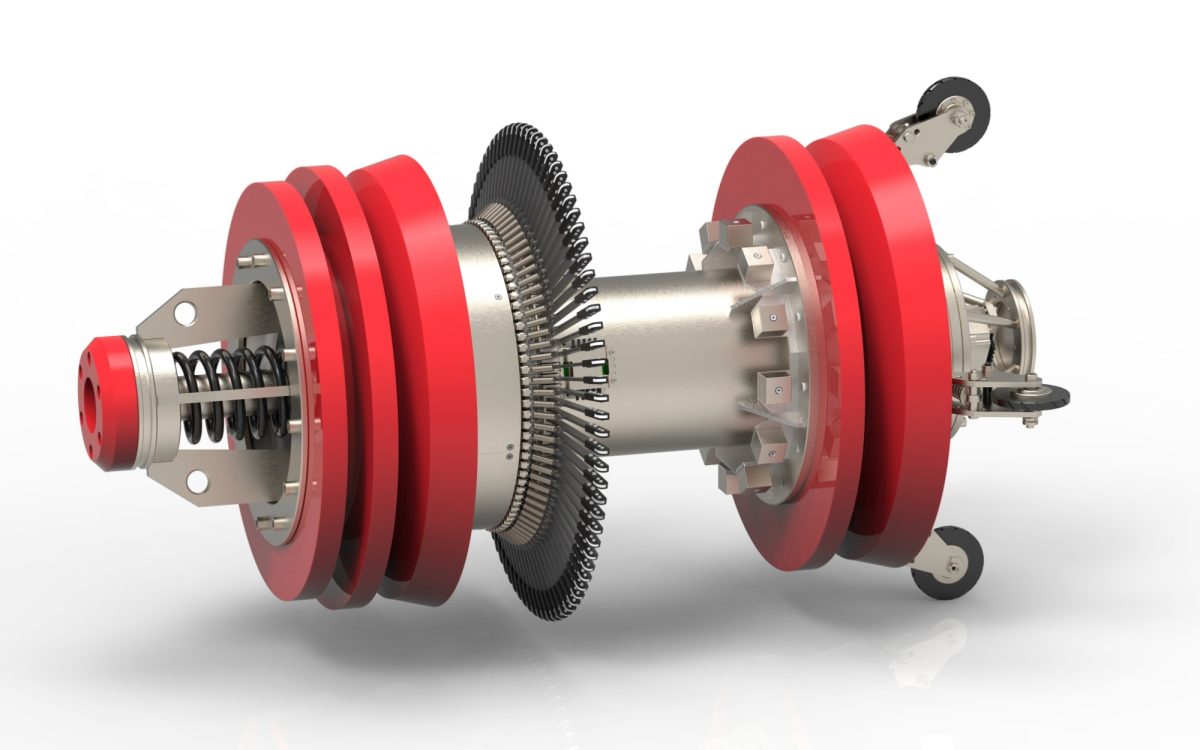

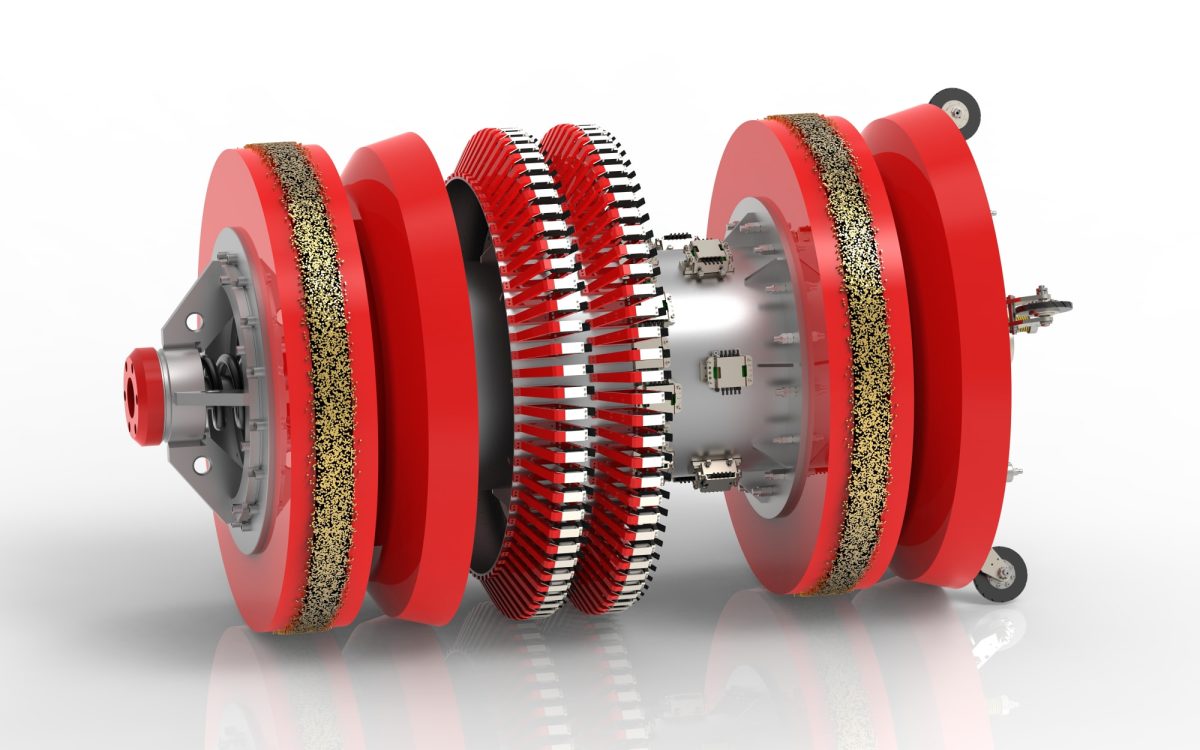

Multi-function drive skeleton:

The tool drive skeleton can not only carry caliper probe, but also carry other functional sensors to complete multi-functional detection. Carrying stress sensors can realize pipeline stress detection. carrying crack detection sensors can realize pipeline crack detection.

Service Advantage

Integrity Data Management:

Provide the basic data of the new pipeline and establish the basic data file of the new pipeline.

Exclusive Customized Detector:

According to the actual working conditions of the pipeline, the detector is customized, and different types of sensors are carried to achieve exclusive customized detection.

Lifetime upgrade and maintenance of analysis software:

Free upgrade and maintenance of customer software, free software consultation.

Exclusive Service Engineer:

Provide professional answers to engineering problems existing on site, and can go to the site at any time to assist customers to solve engineering problems.

Specs.

Technical Parameter

| Maximum operating pressure | Normal pressure |

| Maximum operating time | ≤200h |

| Maximum inspection length | 200km |

| Temperature range | 0 ℃-75 ℃ |

| Minimum pipeline bend radius | 1.5D |

| Operating speed range | Flat pipe: 1.6m/s. climbing slope: 0.3m/s (90°) |

Positioning accuracy

| Axial positioning accuracy at Certainty = 90%. | The distance error between the feature and the reference girth weld is less than 0.1m, and the distance is the nearest reference point ±l*1‰ |

| Circumferential

positioning Accuracy at Certainty = 90% |

±5° |

| P.S:l—Calibration distance | |

IMU accuracy

| Horizontal positioning accuracy | ±1m |

| Elevation positioning accuracy | ±2m |

Gallery

Introduction of Pipeline Inspection

Our professional internal inspection services are available for a wide range of oil and gas pipelines with different pipe diameters, and can address both macro-defects and micro-stresses.